In the world of microfabrication, precision and reliability are everything. If you’ve worked with SU-8 photoresist, you already know that development is a crucial step in achieving high-quality microstructures. But what is an SU-8 developer, and why is it so essential?

This article will break down everything you need to know about SU-8 developers, from their chemical composition to their applications, safety considerations, and alternatives.

Understanding SU-8 Developer: The Chemistry Behind It

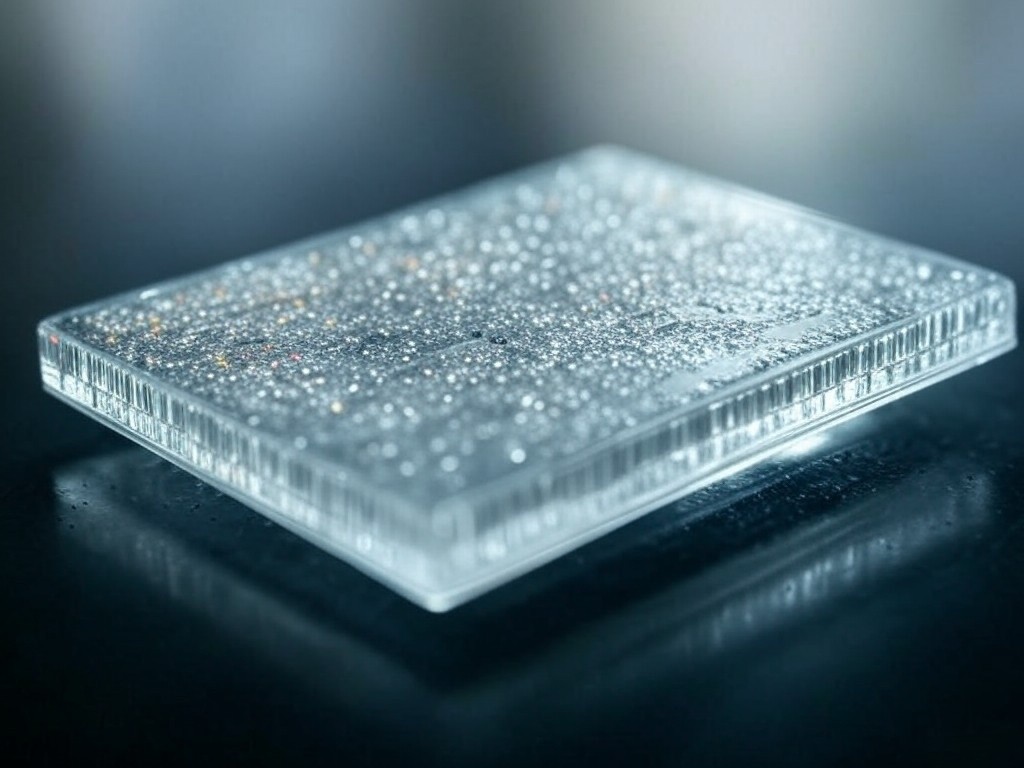

Understanding SU-8 Developer: The Chemistry Behind ItAn SU-8 developer is a specialized solvent used to remove unexposed SU-8 photoresist after UV exposure, leaving behind the desired high-resolution microstructures. It plays a critical role in microfabrication by ensuring that the SU-8 process yields clean, well-defined patterns.

Most SU-8 developers are composed primarily of 1-methoxy-2-propanol acetate (PGMEA), an organic solvent that effectively dissolves the unexposed regions of SU-8 while keeping the cross-linked areas intact.

| Property | SU-8 Developer Specification |

|---|---|

| Main Component | 1-methoxy-2-propanol acetate (PGMEA) |

| Volatility | High |

| Solubility | Organic solvent-soluble, not water-soluble |

| Safety Concerns | Flammable, may cause irritation |

An effective SU-8 developer is necessary for:

Without the right developer, even the best SU-8 formulation will fail to produce high-quality structures.

SU-8 developers are widely used in:

Microfluidics involves manipulating small fluid volumes through microscale channels. SU-8’s ability to form high-resolution microstructures makes it ideal for this application.

MEMS devices—such as pressure sensors, accelerometers, and micro-mirrors—often require precisely defined SU-8 structures, which are achieved through careful development.

SU-8’s biocompatibility allows it to be used in neural interfaces, drug delivery systems, and biomedical sensors.

The high transparency of SU-8 makes it a popular material in waveguides, micro-lenses, and optical sensors.

Yes, SU-8 developers are flammable and can cause irritation if improperly handled. Here are some key safety precautions:

Personal Protective Equipment (PPE):

Storage Guidelines:

First Aid Measures:

| Exposure Type | First Aid Response |

|---|---|

| Skin Contact | Rinse with soap and water immediately. |

| Eye Contact | Flush with water for 15 minutes, then seek medical attention. |

| Inhalation | Move to fresh air and get medical help if symptoms persist. |

| Ingestion | Do NOT induce vomiting. Drink water and seek immediate medical help. |

While PGMEA-based SU-8 developers are the industry standard, some alternatives include:

Each alternative has its own advantages and trade-offs, and the best choice depends on the specific application.

Frequently Asked Questions (FAQ)

Frequently Asked Questions (FAQ)Typically, 12-13 months when stored properly in a cool, dry environment.

No, SU-8 Developer is not water-soluble. It should be rinsed with isopropanol or another compatible solvent.

Exposure times vary based on SU-8 thickness and the UV exposure tool used.

While SU-8 itself can be biocompatible, its developer is not and should be handled with care.

Choosing the correct SU-8 developer is just as important as selecting the SU-8 resist itself. It ensures high-resolution microstructures, minimizes defects, and enhances the durability of the final application.

At Gold One Supplies, we understand the complexities of microfabrication and provide top-quality materials for researchers and manufacturers.

Need SU-8 Developer? Contact us today for expert recommendations and premium-quality supplies!