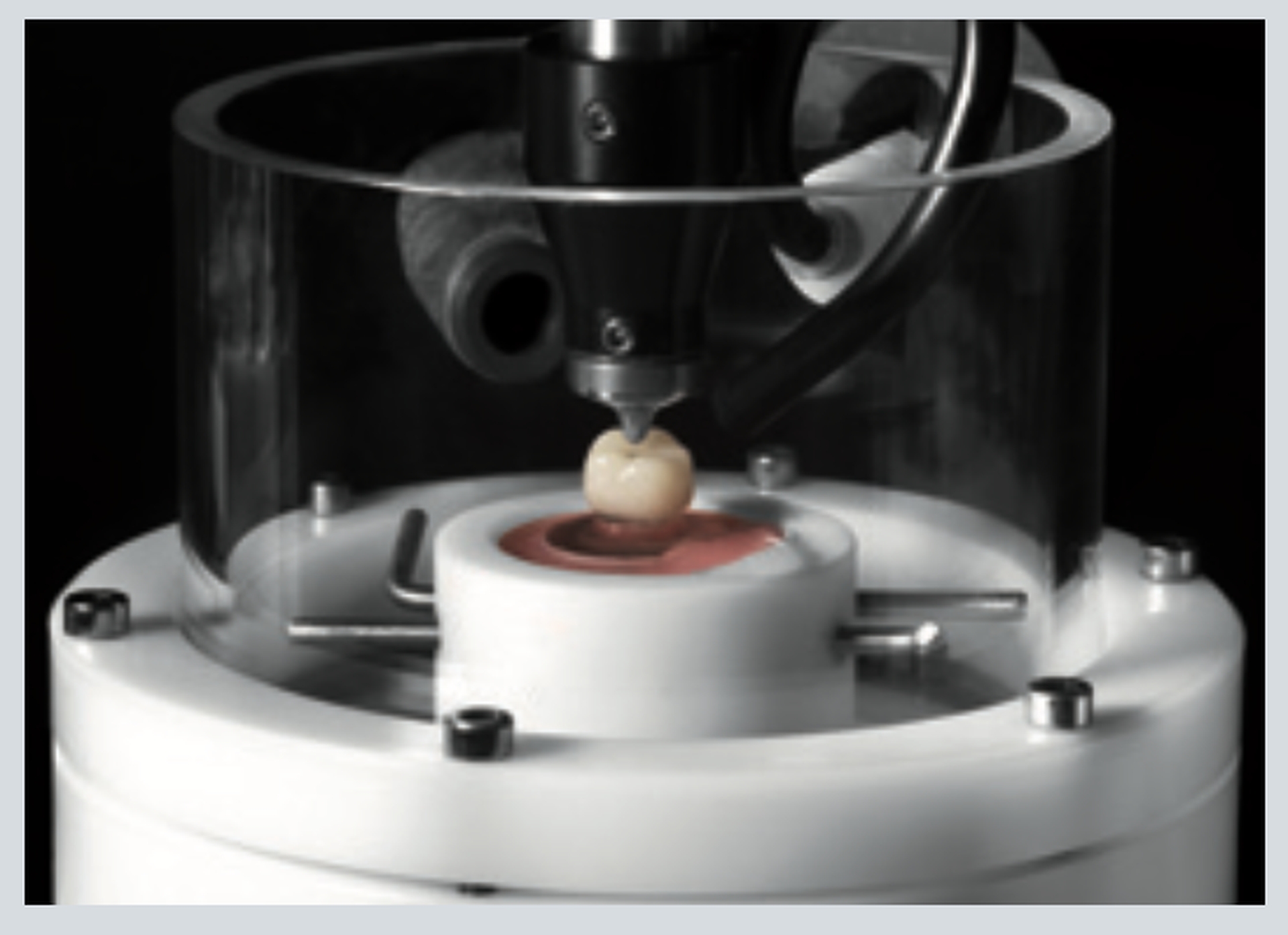

In the continually advancing fields of dentistry and material science, precision and reliability are paramount for driving innovation. The Chewing Simulator developed by SD Mechatronik represents a significant breakthrough, delivering exceptional accuracy in replicating the intricate dynamics of human mastication. Tailored for dental researchers, material scientists, and manufacturers, this state-of-the-art testing device guarantees that dental restorations, prosthetics, and materials undergo thorough real-world simulations prior to being introduced to patients.

Why Chewing Simulation Matters

The human jaw exerts significant force during chewing, subjecting dental materials to pressure, friction, and thermal variations. Without proper testing, restorations and prosthetics may fail under real-life conditions, leading to discomfort, inefficiency, and costly replacements. The SD Mechatronik Chewing Simulator addresses this challenge by replicating these forces with remarkable precision, allowing researchers to:

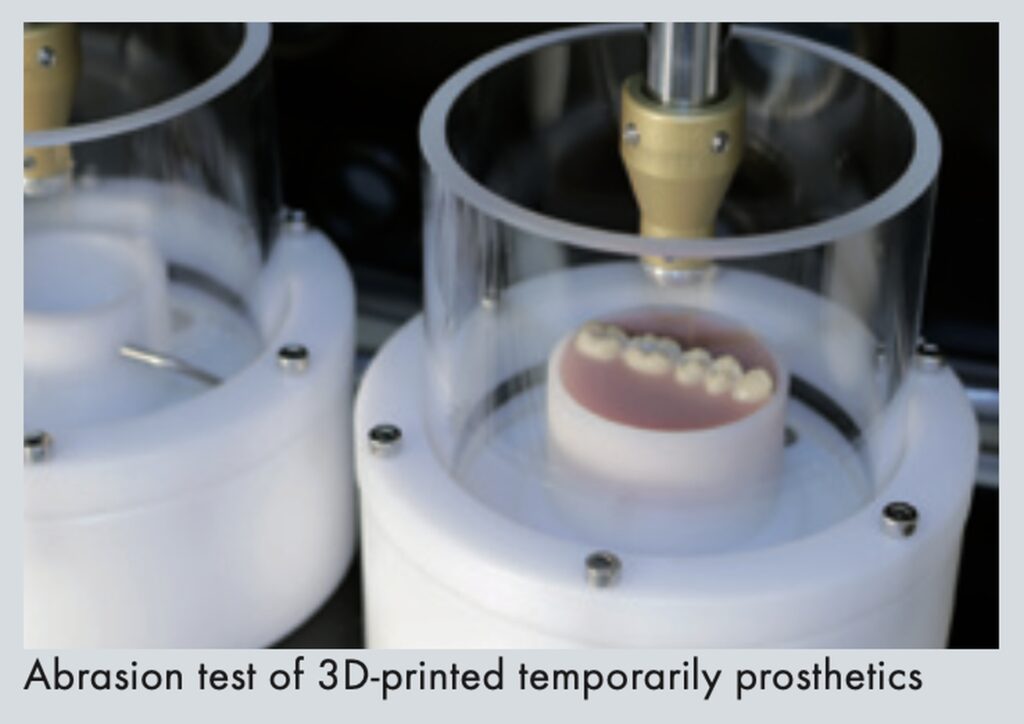

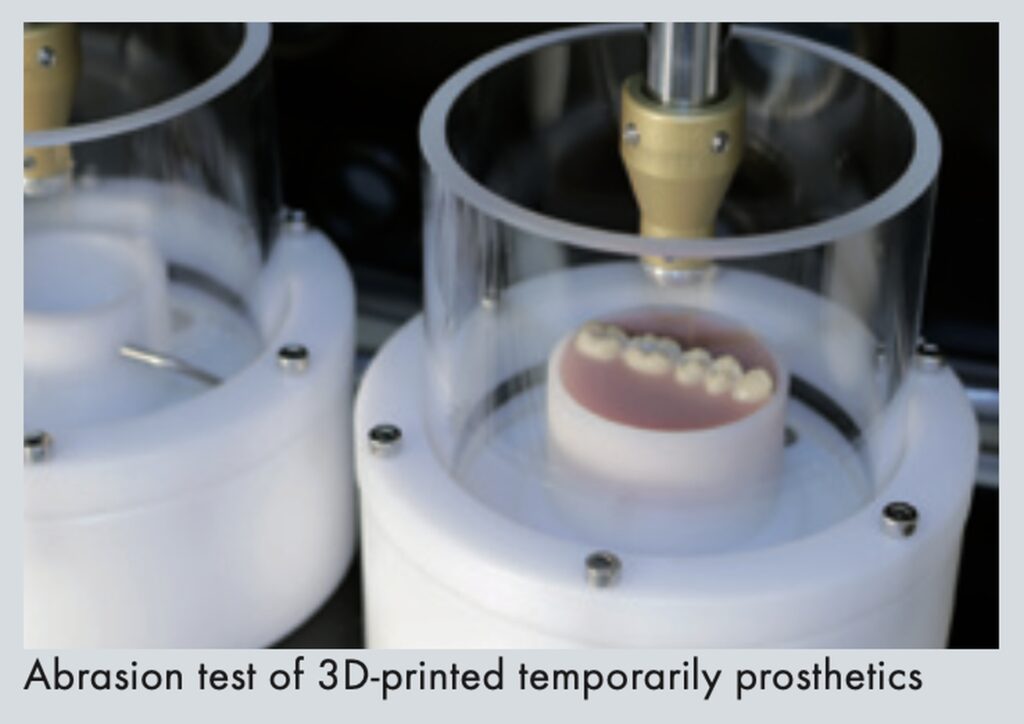

- Assess Wear Resistance – Evaluate how crowns, bridges, and dental composites withstand years of use.

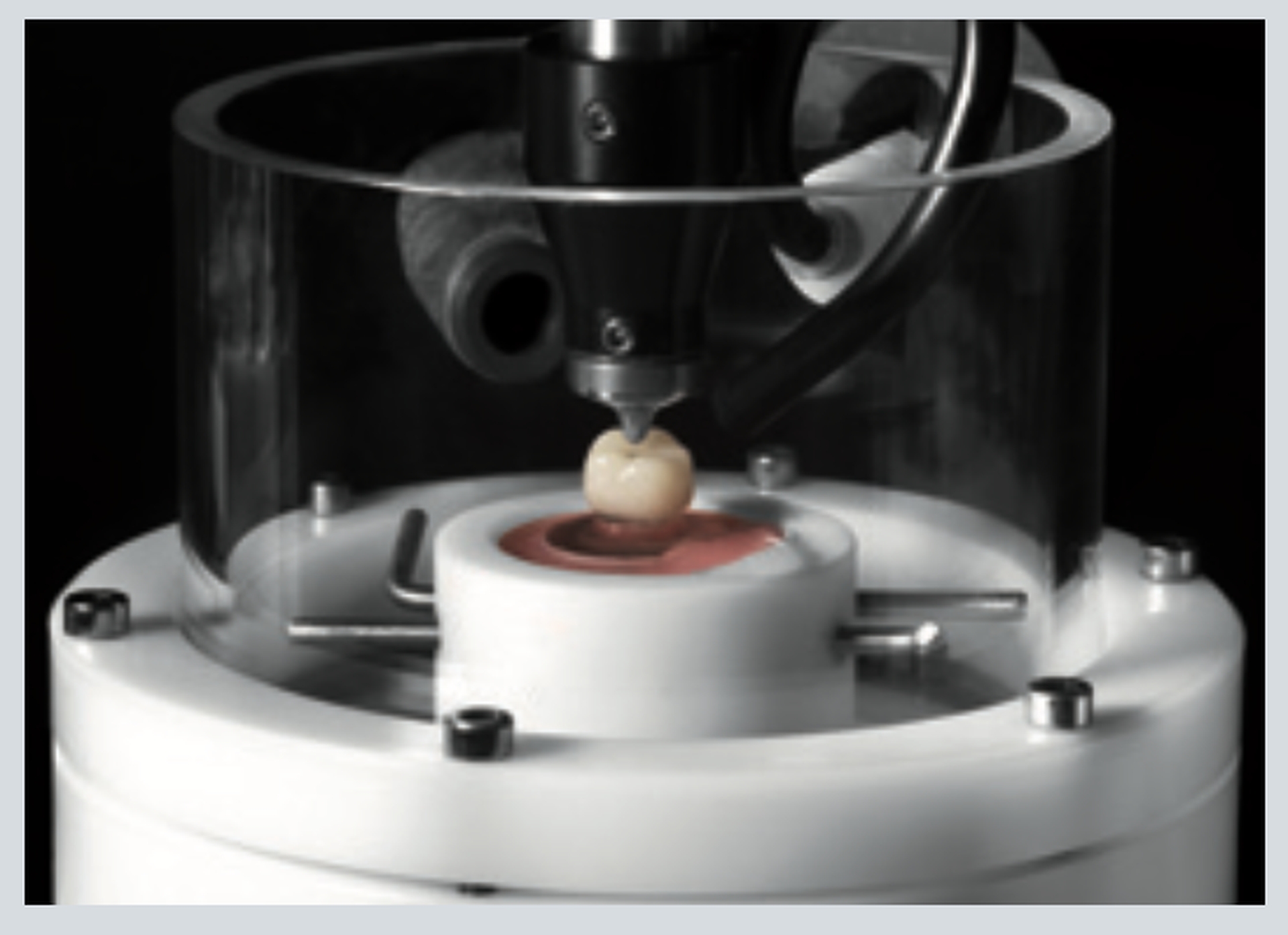

- Simulate Real-Life Chewing Patterns – Mimic human-like occlusal movements to study material behavior under stress.

- Analyze Fracture and Fatigue Strength – Predict long-term performance and durability.

- Perform Thermal Cycling Tests – Replicate temperature fluctuations that materials endure inside the mouth.

Key Features of the Chewing Simulator CS-4.8

Key Features of the Chewing Simulator CS-4.8

This state-of-the-art dental testing machine is equipped with highly advanced features to ensure accurate and repeatable results.

Basic Features

Basic Features

- Low-maintenance drive system – Ensures long-lasting and reliable operation.

- Two independent axes - Allows for complex motion patterns that mimic real chewing dynamics.

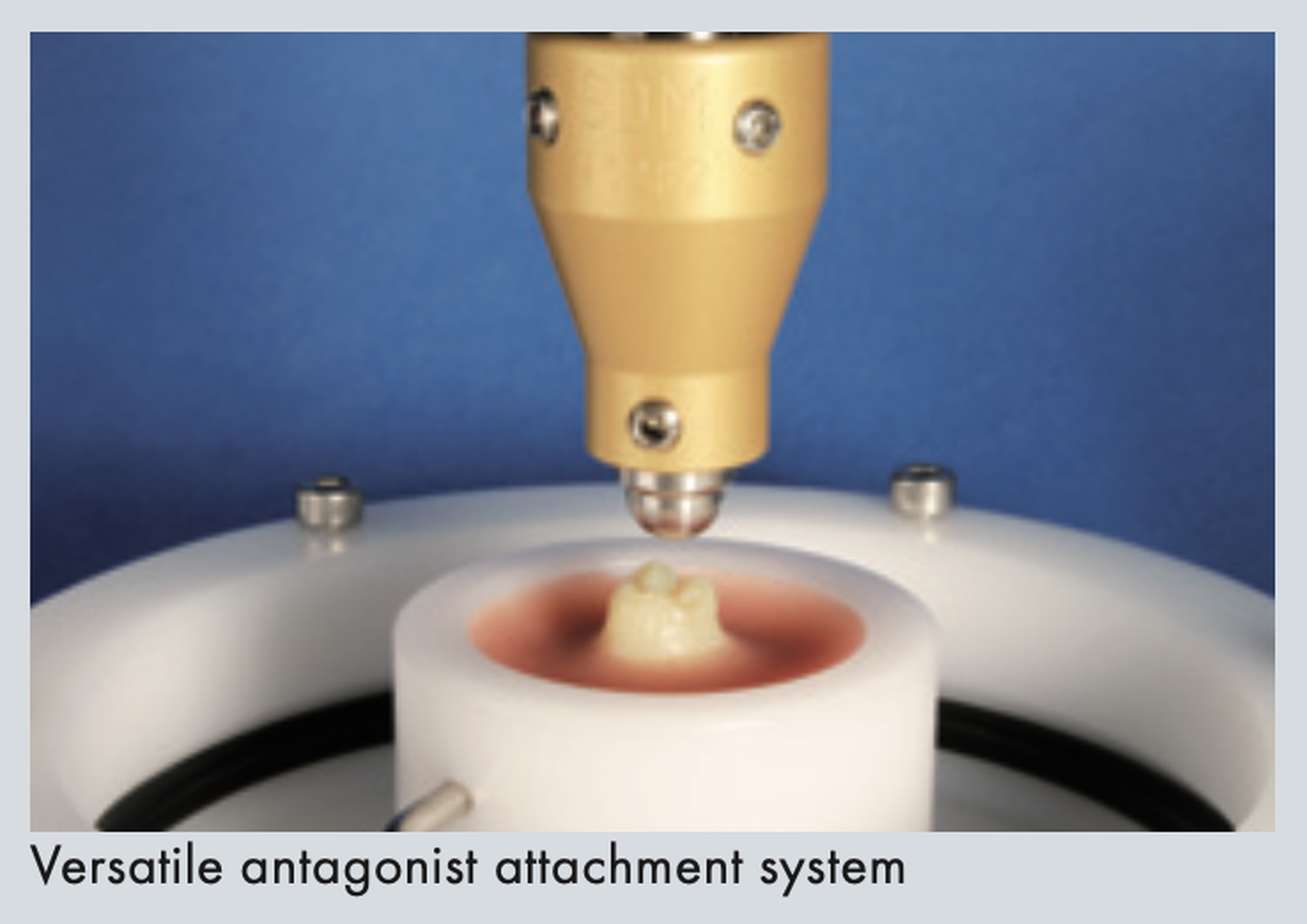

- Eight specimen stations – Each station moves identically, ensuring uniform testing conditions.

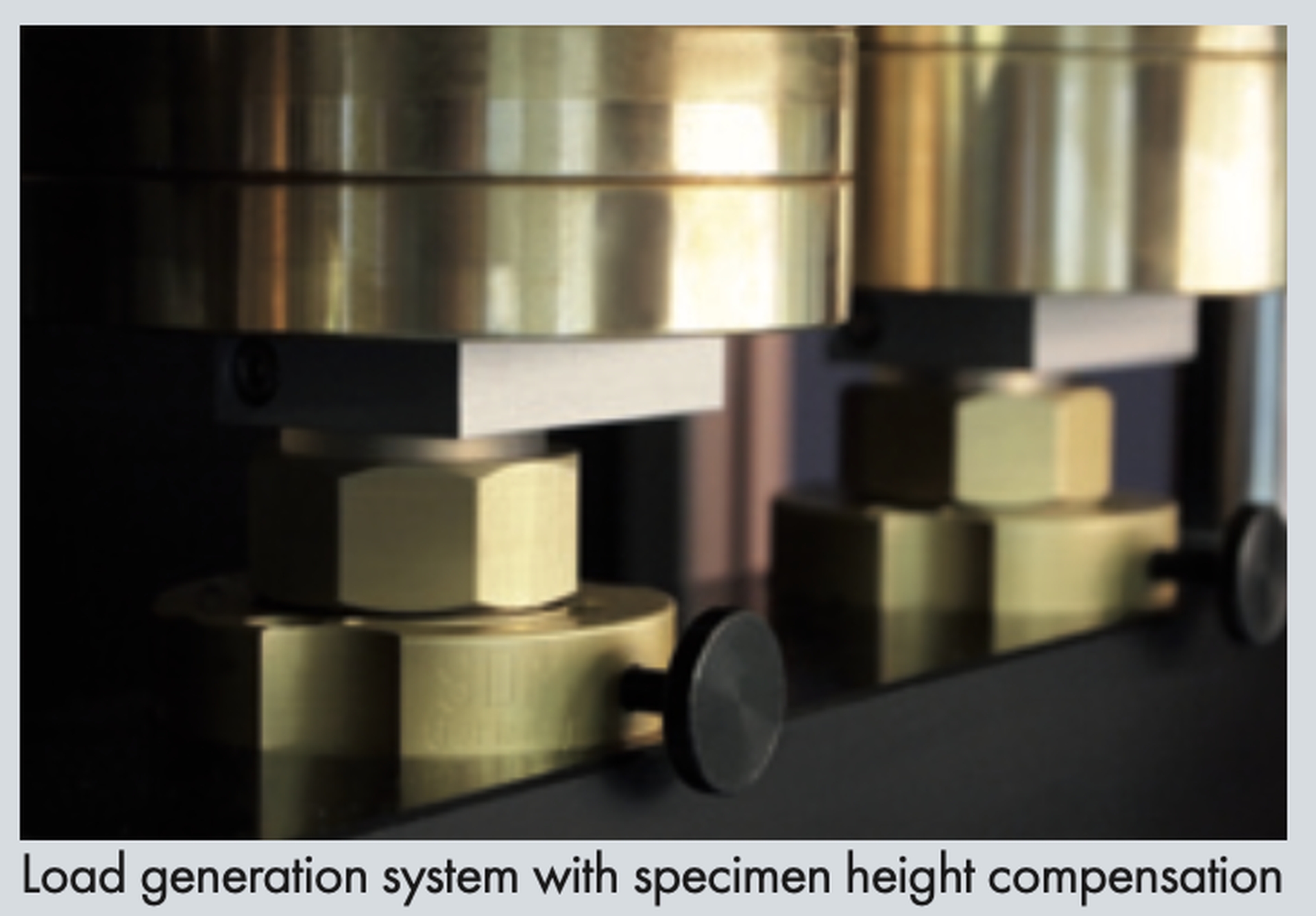

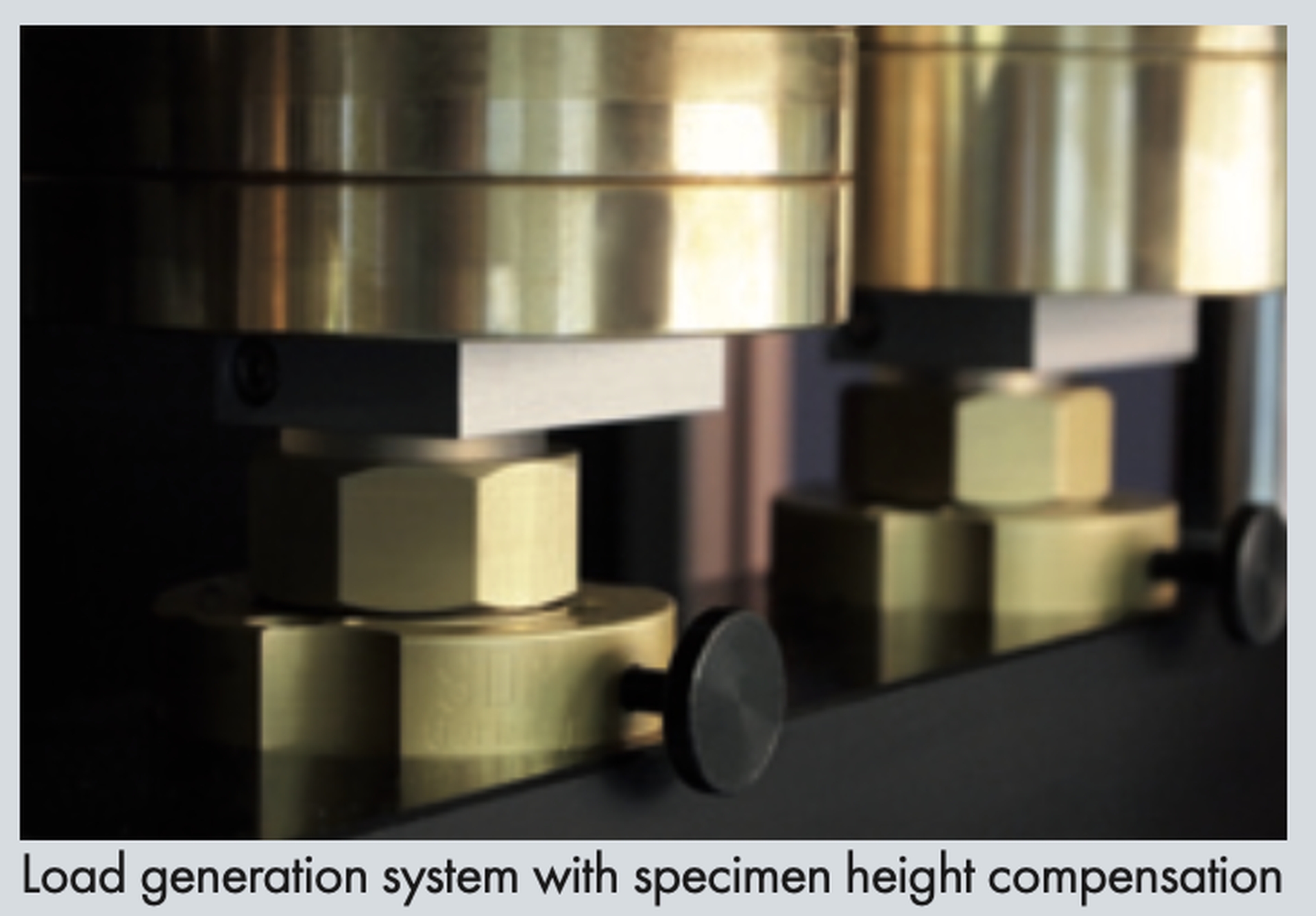

- Vertical load generation – Adjustable weights simulate natural chewing forces.

- Liquid-filled specimen stations – Enhances realism by mimicking intraoral conditions.

User Interface & Software Features

User Interface & Software Features

- 15” Graphical Touchscreen – Intuitive interface for easy operation.

- Integrated Help & Maintenance Assistant – Simplifies troubleshooting and upkeep.

- Data Logging & Protocol Generation – Enables tracking of test parameters and results.

- Remote Access via LAN/Internet – Allows for online updates and diagnostics by SD Mechatronik.

- USB & Ethernet Data Export – Conveniently transfer data for analysis and reporting.

Optional Add-Ons for Enhanced Testing

Optional Add-Ons for Enhanced Testing

- Thermocycling – Simulates temperature variations in the mouth.

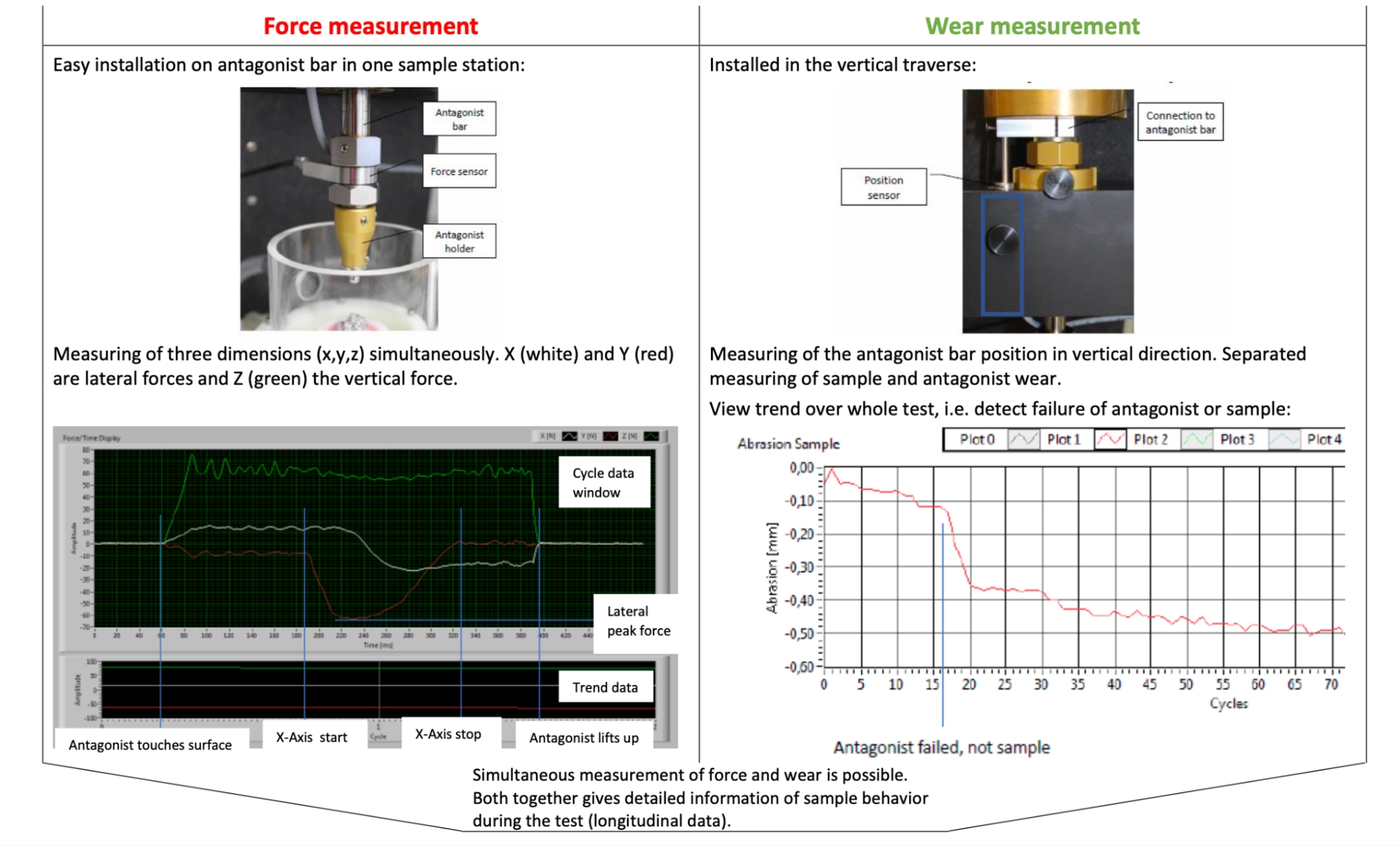

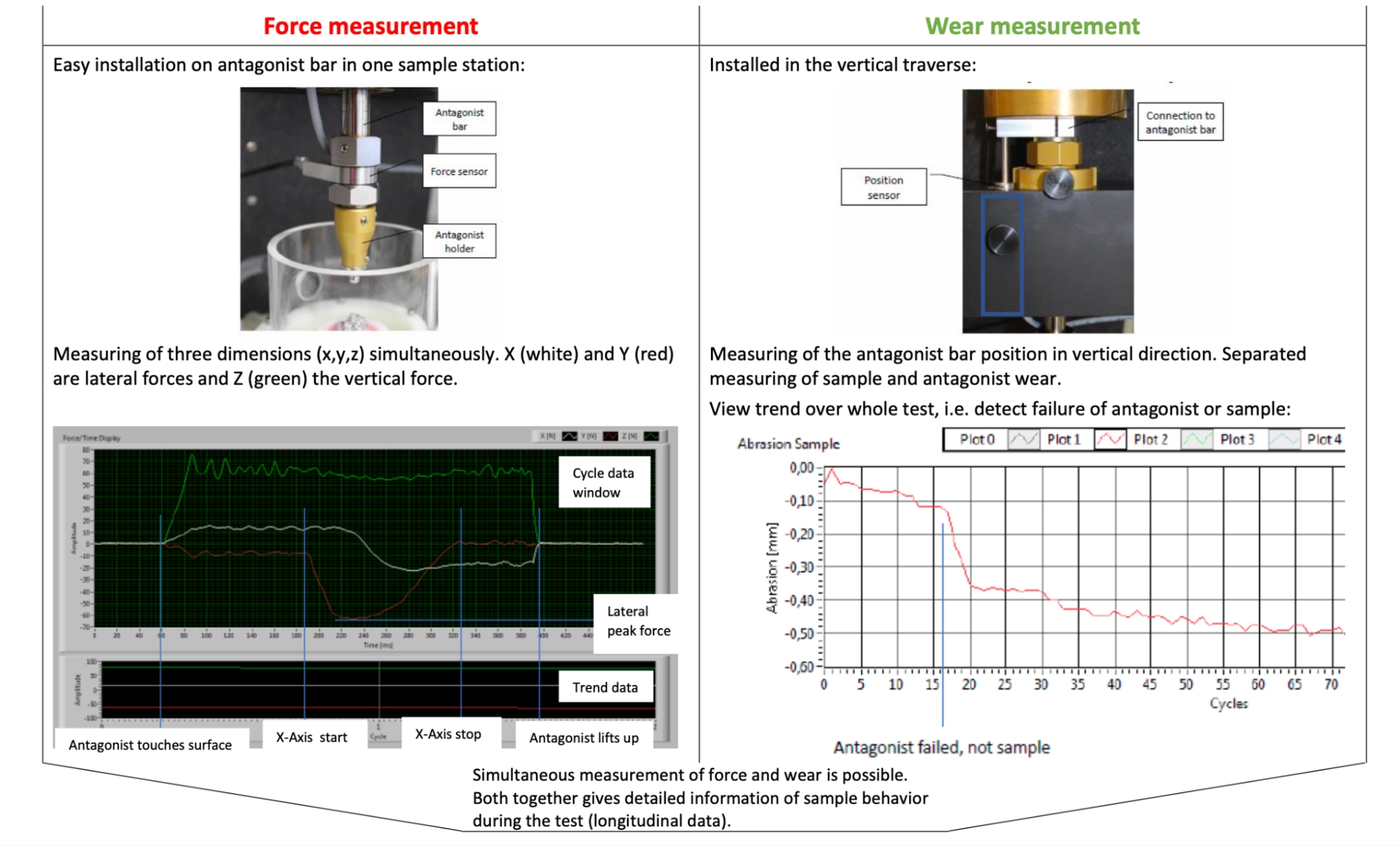

- Wear Measurement – Quantifies material degradation over time.

- Force Measurement – Assesses the pressure exerted on dental restorations.

- High Load Option (250 N) – For extreme stress testing.

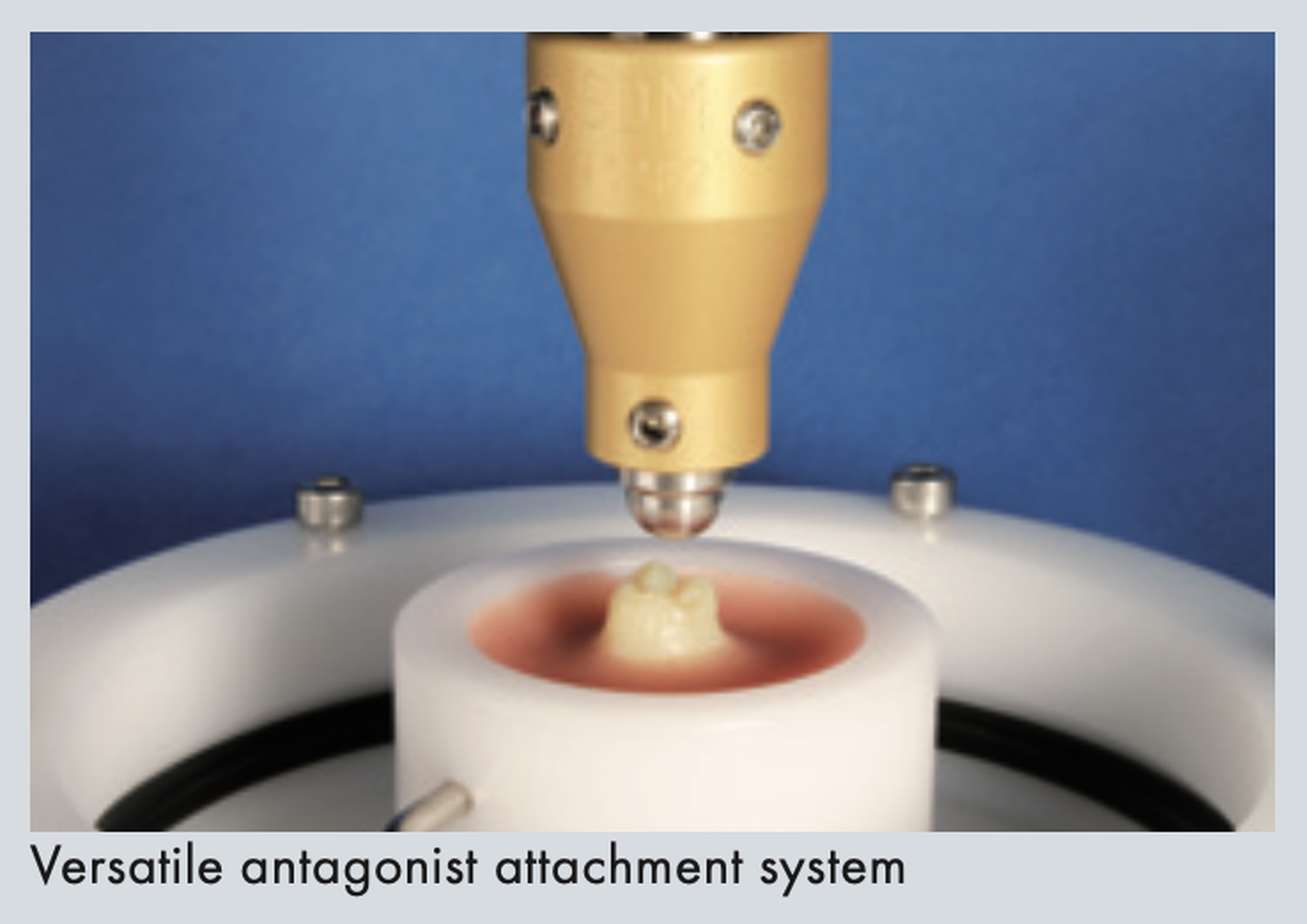

- Custom Specimen Holders – Adaptable to different research needs.

Technical Specifications

Technical Specifications

- Vertical Load Range: 10 N - 90 N (Standard) / Up to 250 N (Optional)

- Speed Range: 1 - 60 mm/s

- Vertical Axis Travel: 0 - 20 mm

- Horizontal Axis Travel: 0 - 20 mm

- Movement Patterns: Single-axis, dual-axis, full and half circular movements

- Specimen Station Diameter: Ø90 mm, Max. Height: 50 mm

- Dimensions: 1600 x 700 x 950 mm

- Weight: Max. 230 kg

- Power Supply: 110 - 240V, 50/60 Hz, 160W

- Max. Environmental Temperature: 40°C

Force and Wear Measurement for Chewing Simulators

Who Benefits from the Chewing Simulator?

- Dental Researchers – Gain deeper insights into the performance of new dental materials and treatment solutions.

- Prosthetic Manufacturers – Ensure that dental implants, crowns, and bridges meet the highest durability standards.

- Universities & Laboratories – Provide students and scientists with cutting-edge tools for research and education.

- Material Science Experts – Test non-dental materials subjected to repetitive stress and environmental conditions.

The Chewing Simulator is setting new standards in dental material testing, offering unparalleled precision, efficiency, and reliability. Whether you're developing new prosthetic materials, testing retention forces, or evaluating wear resistance, this innovative simulator ensures that dental restorations meet the highest quality and durability standards.

Discover How Our Chewing Simulator Can Benefit Your Research

For inquiries or to schedule a demonstration, contact our team today! Take your dental research and material testing to the next level with the Chewing Simulator, where innovation meets precision.

Key Features of the Chewing Simulator CS-4.8

Key Features of the Chewing Simulator CS-4.8 Basic Features

Basic Features User Interface & Software Features

User Interface & Software Features Optional Add-Ons for Enhanced Testing

Optional Add-Ons for Enhanced Testing Technical Specifications

Technical Specifications